Cormak Tytan 750 Vario Milling & Turning Machine

Description

Cormak Tytan Center 750 Vario Turning & Milling Machine

Description

The TYTAN CENTER 750 Vario lathe-milling machine is a combination of two machines, which results into giving nice comfort of use and space-saving workspace. It has a turning smooth speed control and milling spindle.

Turning: 250x750mm, 1.1kW / 230V + Milling: 0.6kW / 230V. Performs turning functions: machining external and internal cylindrical surfaces, cutting threads on them, cutting blanks.

Milling functions: slot milling, drilling and reaming.

It is used in small industrial enterprises, workshops, garages, etc.

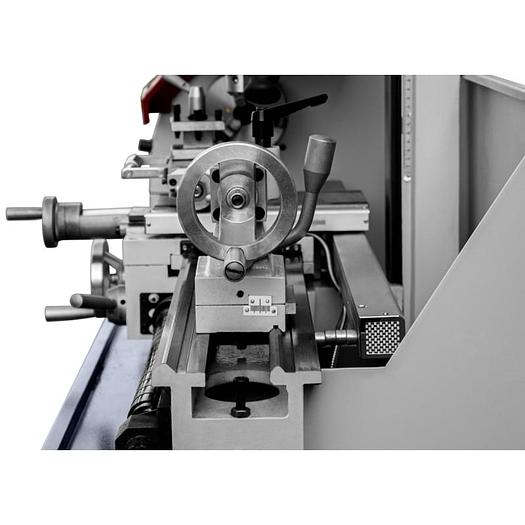

The design of the machine combines two devices - a lathe and a milling machine. Each machine has a separate motor with smooth speed control, which can significantly reduce the time of setting and calibrating parameters. The lathe-milling machine is suitable for the production of parts with a complex configuration, without the need to reinstall it on another machine - which has a positive effect on machining and manufacturing time. The machine has a wide range of applications, starting from sharpening parts, milling grooves, and ending with drilling holes outside the axis and at a specific angle.

Lathe

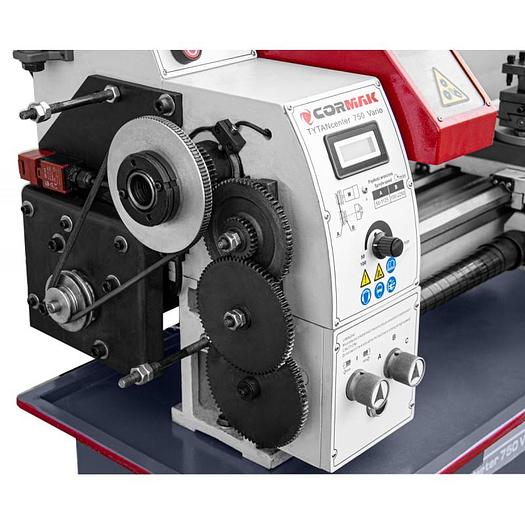

A modern motor with smooth speed control on the spindle ensures comfortable work and shortens the calibration time of the machine.

The LCD screen with the spindle speed display is used to control and quickly adjust the spindle speed while setting the cutting and tapping modes.

Two spindle speed ranges: reduced (50-1125) for machining hard steels and increased (100-2250) for high-speed precision turning.

Cut threads: metric - 18 degrees (0.2-3.5), inch - 21 degrees (8-56) left and right threads can be cut.

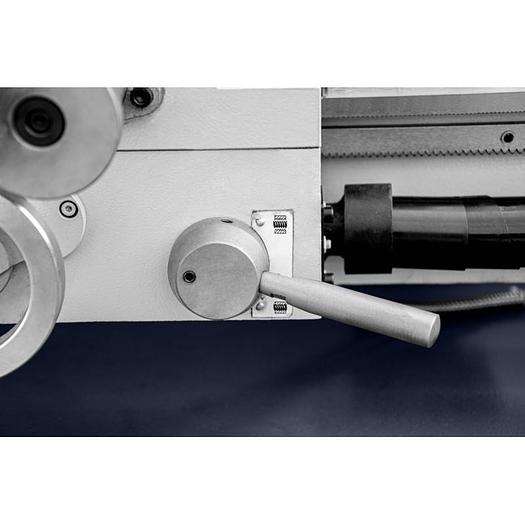

Automatic longitudinal feed has 6 speed ranges (0.07 to 0.40) mm / rev. - Reduces machining time and improves quality when turning long parts.

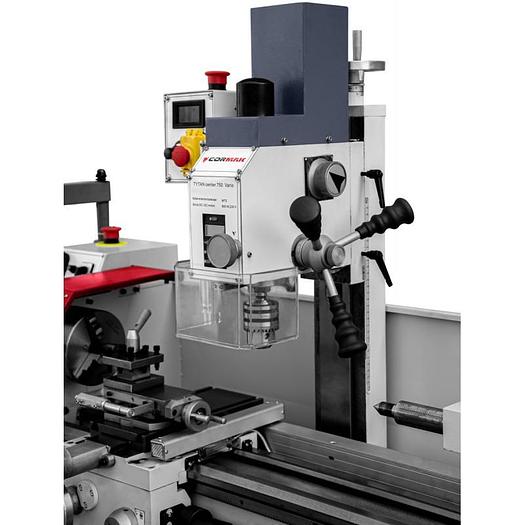

Milling Machine

Modern motor with smooth speed control on the spindle

Two ranges of spindle speed: decreased (50-1125) and increased (100-2250).

LCD screen with spindle speed display is used for speed control and quick regulation

The milling head is equipped with a 2-speed gearbox, which increases the torque when converting power.

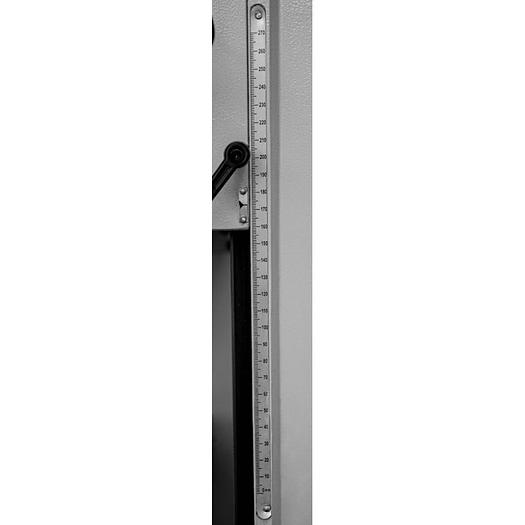

Tool position indicating panel - displays and records the quill stroke with an accuracy of hundredths of a millimeter. This allows you to set exact depth dimensions for drilling and milling and eliminate scrap.

Spindle angle ± 90 ° - this allows you to drill holes and mill at a specific angle.

Rigid movement of the milling head along the dovetail guides ensures high precision and quality of machining.

Before milling, it is necessary to disassemble the tool post of the lathe and install a machine vice in its place. The size of the working surface is 225 x 125mm, the distance between the grooves is 100mm, the groove size is 9x16mm. The maximum lateral displacement of the milling cutter is 115 mm.

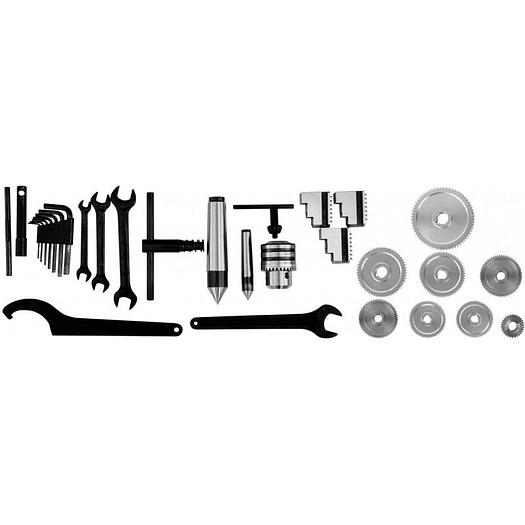

Included Equipment

3 Jaw Chuck

Chuck Key

Hard Jaws

Change Gears

Drill Chuck

Centers

Lathe Technical Specifications

Turning diameter over bed: 250 mm

Turning diameter over slide: 150 mm

Distance between centers: 750 mm

Bed width: 135 mm

Spindle passage: 29 mm

Spindle taper: MT4

Spindle speed control: Smooth (2 ranges)

Spindle speed: 50-1125 | 100-2250 rpm

Number and range of metric threads (18): 0.2-3.5mm / rev

Number and range of inch threads (21): 8-56 ab./cal

Number and range of longitudinal feeds (6): 0.07-0.4mm / rev

Top slide travel range: 70mm

Cross Shift Range: 130 mm

Longitudinal Shift: 630 mm

Tailstock sleeve diameter: 30 mm

Tailstock sleeve advance: 70mm

Tailstock taper: MT2

Handle size: 125 mm

Motor power / supply voltage: 0.75 kW / 230 V

Tool dimension: 12 x 12 mm

Milling Machine Technical Specifications

Max. drilling diameter: 13mm

Max. end mill diameter: 13mm

Max. face cutter diameter: 50 mm

Spindle taper: MT2

Feed the spindle quill: 50 mm

Distance from spindle nose to table: 43 - 250 mm

Distance of the spindle axis from the column: 170 mm

Head rotation: +/- 90 °

Spindle speed range: 50 - 2250 rpm

Dimension and number of T-slots: 8 mm / 2

Motor power / supply voltage: 0.6 kW / 230V

Machine Dimensions: 1,350 x 580 x 1,630 mm

Machine Weight: 230 kg

Specifications

| Manufacturer | Cormak |

| Model | Tytan 750 Vario Milling & Turning Machine |

| Condition | New |

| Turning diameter over bed | 250 mm |

| Turning diameter over slide | 150 mm |

| Distance between centers | 750 mm |

| Bed width | 135 mm |

| Spindle passage | 29 mm |

| Spindle taper | MT4 |

| Spindle speed control | Smooth (2 ranges) |

| Spindle speed | 50-1125 | 100-2250 rpm |

| Top slide travel range | 70mm |

| Cross Shift Range | 130 mm |

| Longitudinal Shift | 630 mm |

| Tailstock sleeve diameter | 30 mm |

| Tailstock sleeve advance | 70mm |

| Tailstock taper | MT2 |

| Handle size | 125 mm |

| Tool dimension | 12 x 12 mm |

| Mill Max. drilling diameter | 13mm |

| Mill Max. end mill diameter | 13mm |

| Mill Max. face cutter diameter | 50 mm |

| Mill Spindle taper | MT2 |

| Mill Feed the spindle quill | 50 mm |

| Mill Head rotation | +/- 90 ° |

| Mill Spindle speed range | 50 - 2250 rpm |

| Machine Weight | 230 kg |