Cormak 350L Sandblaster for Profiles

Description

Cormak 350L Sandblasting Cabinet for Profiles

Machine Type: Sand Blasting Cabinet

Year: New

Machine Description

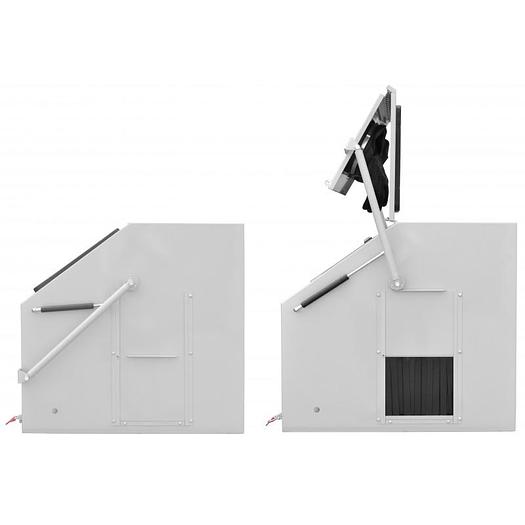

The sandblasting cabin is a device used in industry, car workshops and renovation works. It is used to remove surface layers from various materials, such as metal, wood or glass. The cabin has side openings and telescopic cylinders, which allows the processing of long workpieces. The standard equipment includes a dust extraction system, a set of nozzles, a gun and protective stickers for the visor. Thanks to it, you can effectively and precisely remove surface layers from various materials.

The 350 litre top opening sandblaster for KDP350TOPPLUS profiles is a specialized, reliable and professional tool that will ensure precise and effective cleaning and treatment of metal surfaces. Its advanced solutions and high quality make it one of the best products on the market, which will surely satisfy demanding customers and ensure failure-free and safe operation. The sandblaster is a device that has been specially designed to remove surface layers from various materials. Thanks to the side openings, it allows the processing of long workpieces, which allows for even greater versatility and flexibility in use. Telescopic cylinders are installed in the cabin door, which makes it easier to open and close, and thus increases the comfort of use. As standard, the cabin is equipped with a dust extraction system that protects against inhalation of harmful dust during operation. Thanks to this tool, work is safer and more comfortable.

The dust-free sandblaster is an innovation of the device, which is based, among others, on circumferential seals that guarantee safe and precise processing of various types of surfaces, and thus is a perfect solution for industry, construction and renovation services. The blasting hose is located in the bottom of the collection container, and the drain hole allows for easy replacement of the abrasive. The sandblaster is ideal for removing rust, paint and deposits from metal surfaces such as automotive parts, engines, fittings, housings, wheels, rims and more. Quartz, silicon, glass beads, plastic sand, emery and many other materials can be used for abrasives. This makes the dust-free sandblaster the perfect tool for cleaning and surface treatment, while maintaining an environmentally friendly working process.

Includes

DC15 cyclone exhaust

Foot pedal to control airflow

Working field lighting - 12 V fluorescent lamp with 230 V power supply with switch

2 high-quality work gloves made of rubber, integrated with the device

2 suction (vent) connections with a diameter of 64 mm and 90 mm for connecting a suction device

Sand blasting gun with eight replaceable ceramic nozzles

4 pieces of replaceable protective film for the window, viewfinder

Front door with rubber perimeter seals for dust-free operation

Manual

Technical Specifications

Working Capacity: 350L

Operating Pressure: 4-8 Bar

Air Consumption: 400-700l/min

Air Connection: 1/4" Quick Release

Viewing Window: 580 x 270mm

Side Opening Dimensions: 200 x 180mm

Internal Dimensions Top of Cabinet: 890 x 655 x 350mm

Internal Dimensions Base of Cabinet: 890 x 655 x 610mm

Machine Dimensions: 950 x 720 x 1500mm

Machine Weight: 64kg

Specifications

| Manufacturer | Cormak |

| Model | 350L Sandblaster for Profiles |

| Condition | New |

| Machine Type | Sand Blasting Cabinet |

| Year | New |

| Working Capacity | 350L |

| Operating Pressure | 4-8 Bar |

| Air Consumption | 400-700l/min |

| Air Connection | 1/4" Quick Release |

| Viewing Window | 580 x 270mm |

| Side Opening Dimensions | 200 x 180mm |

| Machine Weight | 64kg |